Technical parameters

| Cutting kerf | 1,8-2,8 mm |

| Bandsaw blade width | 32-38 (51) mm |

| Processing | Primary |

| Tooth finishing | Locker |

| Service and sharpening | Yes |

| Material | RipperS, Bimetal (Ripper37B M42) |

Ripper bandsaw blades can be also purchased online

Normal delivery time

7 working days

Ripper bandsaw blades are suitable for smaller mobile sawmill machines for cutting smaller logs

Features

They are suitable for everyday use and their use reduces energy consumption and significantly increases yield, i.e. minimum waste, maximum cutting performance, the perfect balance of strength and flexibility, more accurate, cleaner and straighter cut and last but not least a better quality appearance of the cut surface of wood, both softwood and hardwood and very hard wood.

Use

These bandsaws are suitable for Wood-Mizer, Pilous, Švoma – Stroje s.r.o.,Baker, Forestor, Timberking, Logmaster, Noorwood, Hudson, Cook, and so on., most portable sawmills and many multi-head sawmilling machines.

Material

You can choose from two types of material – RipperS and Bimetal (Ripper37B M42). We source our bandsaw blades from the world’s leading manufacturer of saw blades, Dakin-Flathers, an English company with worldwide representation. Our company is the exclusive representative for the Czech and Slovak markets.

RipperS

Bimetal (Ripper37B M42)

Advantages

- special metallurgical properties for longer life;

- manufacturing technology designed by Dakin-Flathers;

- use of leading materials;

- blade life up to 42 % longer than competitive products on the market;

- significantly faster cut;

- patented design;

- minimal noise and vibration;

- excellent heat and wear resistance;

- reduced cutting costs;

- increase your profits;

- reduced cutting waste;

- precision in tooth distribution;

- technical support;

- cleaner and smoother cut;

- more successful in material fatigue tests, hardness analysis and strip divorce than competing products.

Service

We are able to offer a professional service for your cutting convenience. Our representatives can help troubleshoot cutting quality issues and blade breakage. We can provide you with grinding – teeth distribution – sharpening – bandsaw blade cleaning.

Grinding

We provide precise and accurate grinding of bandsaw blades with a Shark 600 grinders from the German manufacturer Kohlbacher. The machines are specially adapted based on our experience in servicing narrow bandsaw blades.

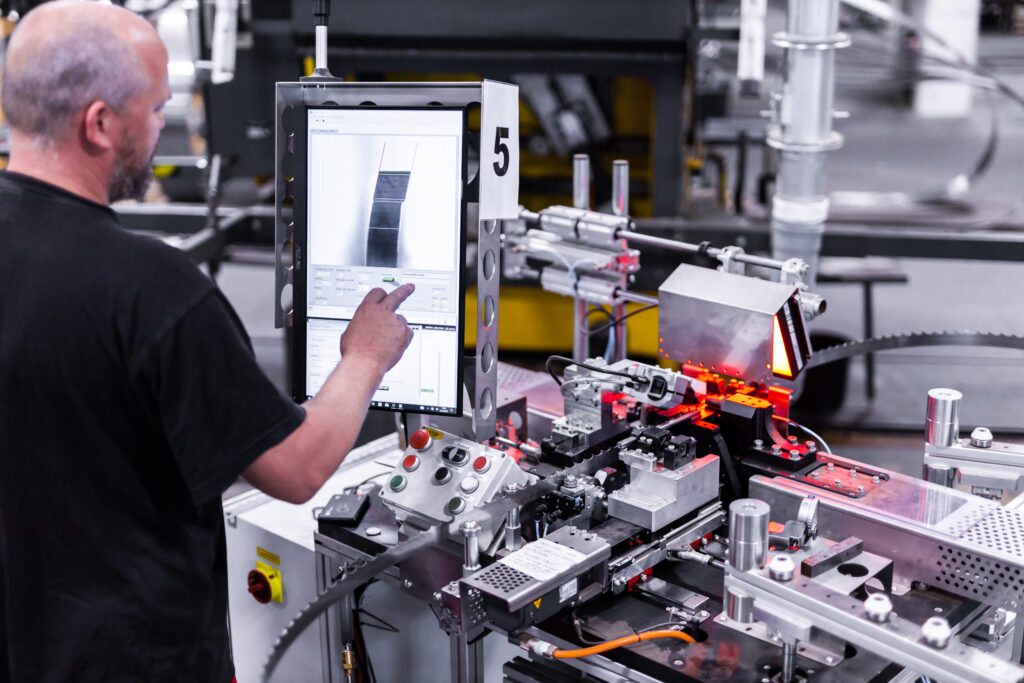

Teeth distribution

We use a machine specially developed by our company that work on the principle of machine processing of the camera image, where we can guarantee precise teeth distribution with an accuracy of hundredths of a millimetre.

Have a question?

Contact us.

Do you have any question? Fill in a short questionnaire and we´ll get back to you within the next business day.