OUR STANDARDS

HEAD

We rely on clever solutions in our work and are constantly improving not only the saw blades themselves, but also the machines on which we manufacture them. With us, every good idea gets the opportunity to prove itself in practice. This approach keeps us constantly moving forward and building our edge over the competition.

HEARTH

We are a great team and we are proud that working for us is a matter of the heart for many. We do everything we can to make sure that we come to work with a passion, enjoy working with our colleagues and look forward to new challenges. We care about personal approach and mutual support, we are open to dialogue. We take care about each customer with an emphasis on their personal needs. We take care about their satisfaction, so that our bandsaw blades do the best job for them and guarantee worry-free operation. With this approach we build a perfect and mutually respected relationship.

HAND

We appreciate the work efficiency of all colleagues in the company. Thanks to our skill, responsibility and good attitude to work, our products allow customers to feel the joy of cutting. We are not afraid to put our hand where it is needed. Whether inside or outside the company.

OUR VISION

“To produce the perfect bandsaw blades”

For us, a perfect bandsaw blade means not only a technically superior product,

but also excellent service to our customers.

We are one of the leading suppliers of bandsaw blades in the world.

Approximately one thousand bandsaw blades of various sizes leave our Sazovice factory daily.

In 2021, the company’s annual turnover reached CZK 100 million. In 2022, the company would like to achieve double its turnover.

We focus on development and innovation of production technologies, in which we regularly invest amounts exceeding CZK 10 million and more. We currently employ over 100 people.

OUR MISSION

“We allow wood to live with people”

Thanks to our bandsaw blades, customers give wood a new life.

Wooden boards, planks or beams become the material for the production of important parts of people’s lives.

HISTORY OF THE COMPANY

The foundations of Dudr Tools were laid in 1992 by designer and toolmaker Ing. Pavel Dudr, the father of the current owner Tomáš Dudr.

The company was located in the premises of the 64th building of the former Baťa plant and at the time of its establishment the original machines were used fot the production of splitting and tanning knives. By a lucky coincidence, the then owner was approached with an individual order to produce a bandsaw blade and thus discovered the true purpose for which the old technology was originally used.

In 2005, Pavel Dudr handed over the complete management of the company, which had six employees and a turnover of around CZK 3 million, to his son Tomáš, who was involved in the production of grinding machines and bandsaw blades.

The dynamically developing company gradually became an important supplier to the engineering and woodworking industries.

In 2010, Building 64 became too cramped; for example, employees had to carry bandsaw blades to turn them outside the building. A solution was urgently need.

At that time, the company had the opportunity to use the vacant space on the 5th floor in the neighbouring building 63. Initially, the company rented 600 m2 in the west wing of the floor, later it also used the middle of the floor and soon the eastern part. In this way expanded its production area to a total of around 1,300 m2. But even here the conditions for industrial production were not ideal.

The company was growing at a very fast and it was clear that space would soon be at a premium again. Loading and unloading the company´s fleet of vans (six at the time) was complicated by the external lift, which had long since outlived its useful life. Over time, the space requirements became so critical that the bandsaw blades were taking over the adjacent stairwells and other areas.

After looking at several properties for sale, the management decided to build their own production space fully meet the needs and requirements of production. In 2016, after a long search, the company managed to buy a plot of land in Sazovice.

The construction of the production hall started in November 2017. On Friday, 3 August 2018, the technologies in the former Svit plant were shut down and on Sunday, 5 August, the first night shift od production in the new Sazovice plant started. A new phase of Dudr Tools business has begun.

Already in its first year in Sazovice, the company managed to surpass the important milestone of CZK 100 million turnover. Today, in 2022, the company has set itself the goal of doubling this figure.

The company has never backed away from its very dynamic growth and does everything in its power to manage and coordinate it effectively. As a result of this growth, a natural expansion of production is planned for the beginning of 2021.

In April 2022, with 100 employees, the company completed an extension to its production hall, doubling its space and entering the next era of its history. By the end of 2022, the production halls are fully equipped with production machinery and the company reaches a full and compliant state with over 100 employees.

PRODUCTION

Dudr Tools has been operating in the engineering and woodworking industry since 1992.

Our portfolio includes the production and service of bandsaw blades and circular saws for cutting wood.

We export our services and products to Romania, Lithuania, Holland, Finland, Australia and other countries.

Our customers range from the smallest DIYers to the top companies processing hundreds of cubic meters of wood per day.

But the cooperation does not end with the delivery of the tools themselves. We also look after them throughout their life to ensure they continue to perform at their best.

We are also involved in the service of various tools for the woodworking industry, from circular saws to planing knives to various chipping knives for chippers.

All these products are manufactured on machines that are freely available on the market.

These are various special purpose machines such as CNC grinders, TIG welding of bandsaw blades, resistance welding machines and other special purpose machines.

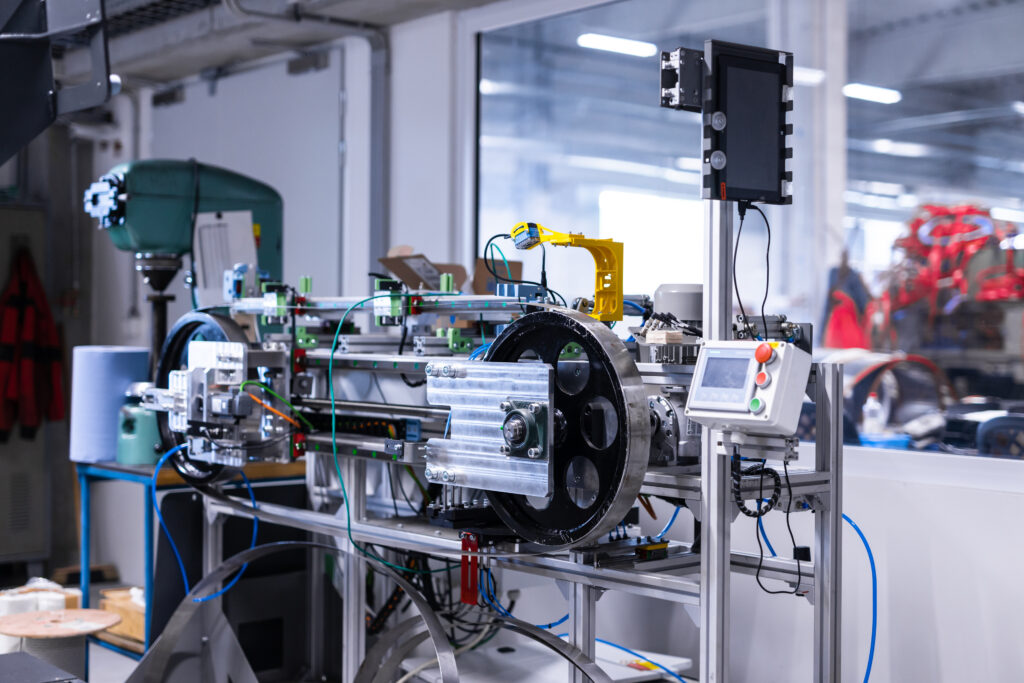

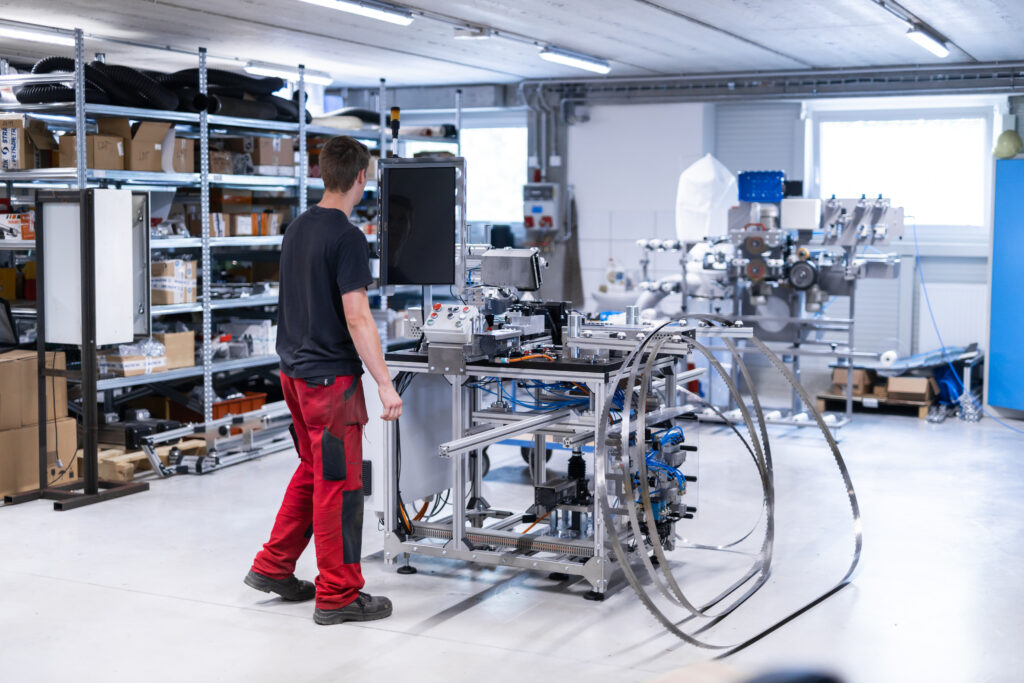

DEVELOPING OUR OWN TECHNOLOGIES

As we strive to deliver the highest quality products to our customers, the technologies available on the market have become less suitable over time. We therefore set about improving our own production machinery and processes.

This has led us to develop our own machines to meet the most demanding requirements that are now a necessity in any modern company (remote machine control, information retrieval from the company system, camera measurement, automatic machine adjustment, etc.).

Our designers work to develop machines and systems that they then see their colleagues using in the field, observing their daily shortcomings and advantages. This enables them to respond to production requirements and gradually fine-tune everything to perfection.

Each subsequent creation from our production naturally incorporates the knowledge of previous models, making everything more user-friendly and technologically advanced.

The aim of developing our own machines is to make the work of our colleagues as easy as possible and to offer the most advanced tools on the world market.

The expansion of production in the newly completed extension of the production hall also allow us to create a centre for our own development activities in the field of machine design, which should contribute to ensuring a higher proportion of robotics in our company in the future.

APPROACH TO THE CUSTOMERS

Our strength in the supplier-customer relationships lies in our personal and individual approach to the customers.

Our priority is always to satisfy the customer and to understand their needs and requirements.

Thanks to our own development, we are able to transform and materialise ideas into real forms.

We strive to build close and friendly relationships that lead to the long-term cooperation.

Our employees make a significant contribution to this. They are professionals with a practical approach that is often overlook by competitors.

OWN DISTRIBUTION

We have our own weekly delivery service throughout the Czech Republic, Slovakia, Poland, Austria and Germany.

We are flexible in terms of time and we understand that your machines should not be idle, but should be working at 100 % performance all the time.

That’s why we have our own fleet of vehicles, manned by our drivers, which are always on the road and available for the transport and delivery of bandsaw blades.

For other deliveries of bandsaw blades abroad, we use the services of external transport companies.

WE ARE GOOD

The fact that we are a great bunch here proves that we like to get together not only at work, but also at various events.

The first company slaughter was a great success.

We find ways to make our lives more enjoyable and have fun.

On several occasion we have rented ice at the ice rink so that all members of the Dudr Family could skate in peace.

For sports enthusiasts and fans we organize, for example, a Cycling Day with Dudr…

By far the most popular annual event is the Family Day in the entertainment complex.

…where the endorphins at the finish line are definitely not lacking.

We don’t need other people’s voices for radio spots. Our voices are spoken directly by our staff.

We do not forget the employees´ birthdays…

We reward our employees for different work anniversaries.

…or the St. Nicholas, Christmas, Easter, International Women´s Day and other holidays.

We educate together and learn from ourselves.

We don’t forget the jokes, because everything goes better with a smile on your face.

With Dudr we go on adventures in Czech meadows and groves, but also abroad.

We get used to media interest and learn to stand in front of the camera.

Life is beautiful and every day there is a reason to celebrate.