Technical parameters

| Cutting kerf | 1,2-1,8 mm |

| Bandsaw blade width | 50-100 mm |

| Processing | Secondary |

| Tooth finishing | Stellited |

| Service and sharpening | Yes |

| Material | Uddeholm, 80NiCr11, EHS |

Ripper bandsaw blades can be also purchased online

Normal delivery time

7 working days

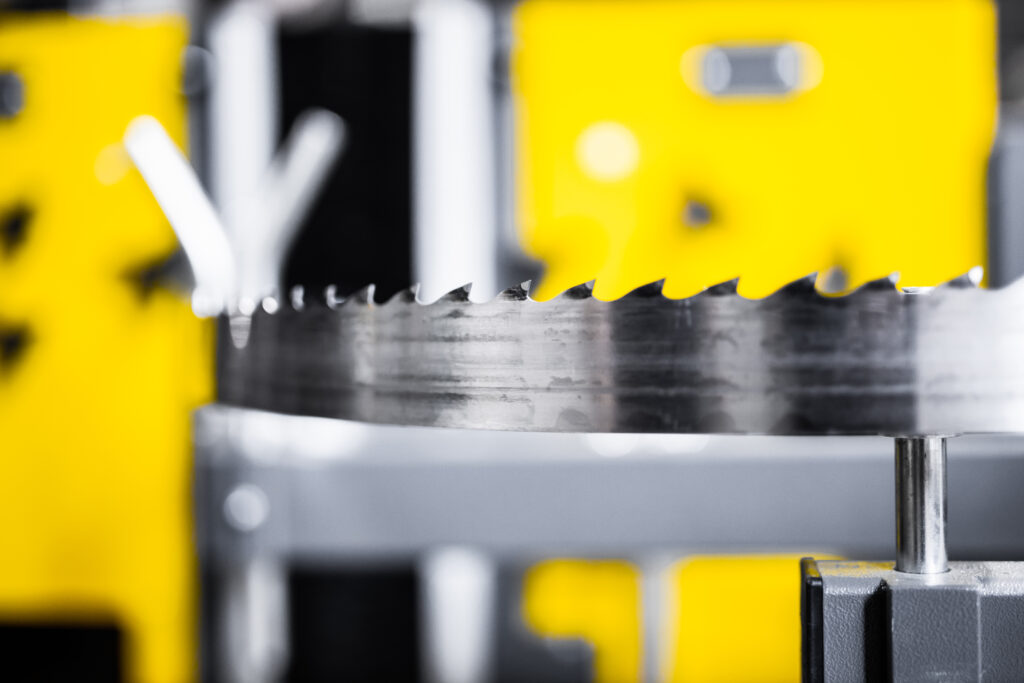

Thin-cutting bandsaw blades are specially developed for the maximal efficiency of CNC bandsaw machines.

Features

Designed for secondary wood processing. They are used mainly for the processing of precious and exotic materials with demand on high accuracy and quality of the cut for example when manufacturing parquets, floorboards etc. For the production of our bandsaw blades, we use exclusively high-quality materials from renowned manufacturers such as Swedish Uddeholm, a flagship in the field of bandsaw blades.

Custom made production

We produce custom-made bandsaw blades according to customer needs with regard to cutting accuracy, speed, quality or cleanliness of the cut. They are suitable for all types of thin-cutting bandsaw machines such as Wintersteiger, Fill, Neva, Stenner, Centauro, etc.

Use

We offer bandsaw blades with a cut ranging from 1.20 to 1.80 mm. Tooth pitches 25, 30, 35 mm or variable tooth pitches. Tooth profile according to the desired application (hardwood, softwood, dry, wet, etc.).

Service

We provide full-scale servicing of thin-cutting bandsaw blades. For example, levelling and tensioning, which compensates for the unevenness of the belt body and gives it sufficient tension to ensure its stability in the cut which straightens any irregularities of the bandsaw blade and provides the bandsaw blade with sufficient tension, ensuring the blade ´ s cutting stability. We also provide a repair service for bandsaw bodies, sharpening and we can renew the stellite.

Have a question?

Contact us.

Do you have any question? Fill in a short questionnaire and we´ll get back to you within the next business day.